Nowadays, the main task of a locksmith is cold metal processing – manually or with the use of power tools. The scope of work of a locksmith includes small parts of mechanisms, minor machining and manual processing of steel, stainless steel and aluminum surfaces.

A locksmith is treated as a welder’s assistant, because he is very often responsible for preparing materials for welding and their subsequent processing in order to apply protective coatings.

The very wide range of skills that a locksmith must have include everything related to mechanics (assembly and disassembly of devices), cutting, sawing, drilling, riveting, soldering and skills in the field of electrical engineering and hydraulics. Also metal science is a very important field of knowledge that a locksmith must acquire – testing the hardness, strength, elasticity, impact strength, plasticity and other basic characteristics of metals is the knowledge necessary for the proper performance of locksmith’s profession.

marxam project

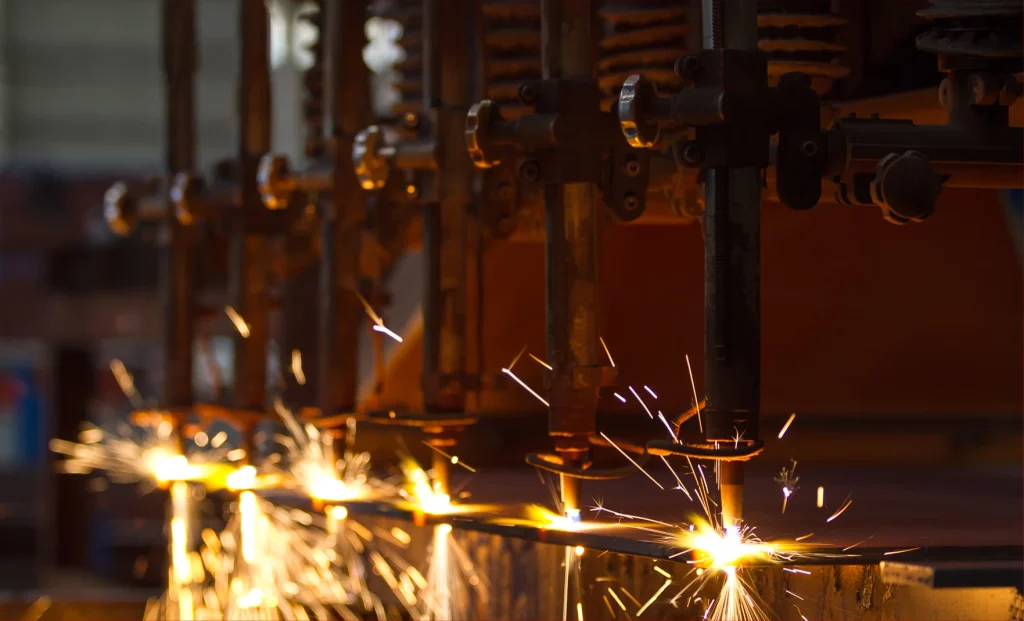

thermal and jet processing

laser cutting

Sheet metal

laser cutting

Sheet metal laser cutting is a technology that allows you to quickly and cheaply obtain an element of any complex shape from various types of flat sheets.

The undoubted advantages of laser cutting are:

- cutting laser offers freedom of shapes, limited only by the properties of a given material;

- cutting metal with repeatability of details at the level of 100%;

- for given types of materials and their thickness, the laser cut surface is of a quality that allows the elimination of the finishing process;

- the best possible use of the surface of the material – thanks to the use of appropriate computer programs, with our laser cutting services, we obtain a very large percentage of sheet metal use, and we can properly optimize the production process;

- lasercutting allow to reduce the effect of heat on the deformation of the cut material;

- laser metal cutting offer very high flexibility in the number of produced elements – one piece or several thousand does not make any difference in technical terms for cutting metal with laser;

- engraving of elements – during the laser cutting process, the element marking technique can be used immediately.

- universality in material available for cutting – you can easily use it for steel laser cutting, laser cutting of sheet metal, for laser cut metal and many more.

Laser cut companies have become quite prominent in metalworking industries. Choosing Marxam Project, you are choosing a reliable partner with decades of experience in the process of laser cutting.

Allows you to quickly and cheaply obtain an element of any complex shape.

do you need this service?

laser cutting technology

Laser cutting pipes

and 3D profiles

The technology of laser cutting pipes and profiles has two main advantages compared to traditional processing methods:

- tube cutting allows for a significant reduction in the costs of preparing sections for further production;

- laser tube cutting services allow the use of many new construction and technological solutions.

Our 3D laser profile cutting and 3D welding systems are ideal for machining 2D and 3D components or tubes. The ability to flexibly switch between cutting, welding and laser cladding allows for maximum production efficiency, and the dynamic, optical cutting system significantly reduces processing time.

An additional advantage of industrial laser cutting for serial production is the possibility of working in a rotational mode – during the operation of the machine, it is possible to unload and load new elements for processing.

Pipe cutting, laser 3d profile cutting, laser cutting tubes and many more. Our company offers a wide variety of services related to laser cutting in the industry of metalworking. Choosing us, you are choosing a reliable and experienced partner with decades of experience.

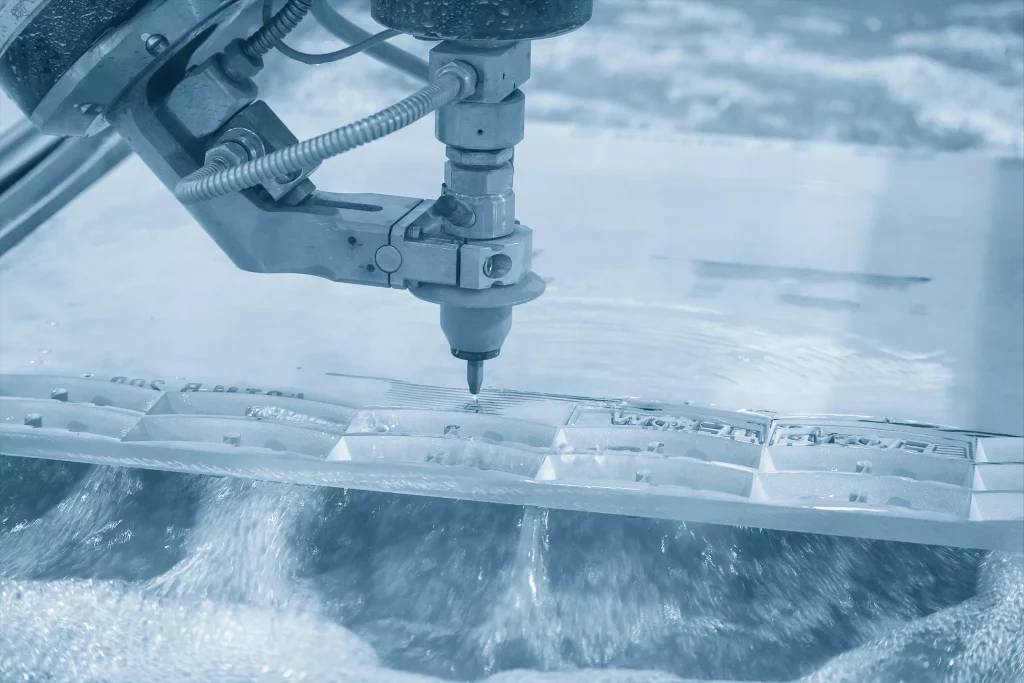

Water jet cutting technology

Water jet

cutting

Water jet cutting services allow to ensure high quality of the machined surface for details with large thicknesses and complex geometric shapes (high density of cutting lines on a small area, small diameters of holes – of the order of even 1mm).

The use of aqua cutting with very high pressure, containing fine abrasives, allows to achieve new production effects, which were impossible or very time-consuming and expensive using other methods.

Using this method, we can process, among others, such materials as:

- Ceramic materials;

- Glass;

- Plastics;

- Titanium and titanium alloys;

- Materials sensitive to high processing temperatures;

- Structural, alloy and tool steels (of any degree of hardening);

- Cast iron, cast steel;

- Copper, brasses, bronzes;

- Molybdenum and molybdenum alloys;

- Wood and wood-based materials (plywood, MDF);

Waterjet cutting technology is one of the most environmentally friendly processing methods. The abrasives used are of natural origin and are chemically inert, and the process itself does not generate any harmful waste.

If you are looking for a high quality cutting method, while protecting the environment – aqua jetting is for you. Cutting with water is the perfect solution for the new generation of environmentally educated people.

Sheet metal laser cutting

Sheet metal

laser cutting

Innovative technology is used in most services. Sheet metal laser cutting is no exception. It is no different with the metalworking industry, which, until several years ago, used mainly traditional machining methods. Although Marxam Project knows and is able to use most of the old methods, in the implementation of projects it focuses on modern solutions, such as metal laser cutting.

Laser cutting not only guarantees the high quality of the commission, but apart from significantly shortening the production time, it brings a number of other advantages that are not possible to obtain using traditional machining methods.

What is laser cutting?

Laser cutting process involves the use of innovative technology for precise and effective heat treatment. Thanks to lasercutter – machine equipped with laser beams, sheet metal is cut, which can be characterized by various parameters. What is worth emphasizing, is that cutting metal with laser itself is fully automated in terms of repeatability of the same product, and this means that sheet metal cutting minimizes the risk of errors in the implementation of large projects.

Laser cutting of sheet metal - application

Precise laser cutting of sheet metal and the associated repeatability make this type of service applicable practically everywhere. Lasercut sheet metal is a significant technological leap in mass production – lasercutting allows you to significantly shorten the time of production of elements and to be sure that each element cut with a laser will be the same and repeatable. Marxam Project offers laser sheet metal processing for e.g. automotive, agricultural and aviation companies, production plants or fuel and energy concerns and mining plants. Process of laser cutting to size can also be used in less obvious industries, e.g. in the furniture industry, health care or in catering establishments.

Laser cutting services - advantages

- Laser cutting of sheet metal reduces the impact of heat on the material being processed.

- Can be used in various types of materials – from aluminium, metal and metal alloys to glass.

- When deciding to laser cut sheet metal, it is difficult to talk about limitations in terms of shapes – the only barrier is the properties of the material used.

- Cutting metal with a laser is a fully automated process, which guarantees maximum repeatability and 100% precision in the execution of all details related to the entrusted project.

- The radiation beam during laser cutting for steel is adapted to the type of material and its surface thickness, which allows for a significant reduction in the cost of finishing.

- Thanks to precise laser cutting, you can make a solid cost reduction, which results from the aforementioned repeatability. The risk of losses is minimized practically to zero – the lack of damage to the material allows it to be used in other projects, not only for laser cut metal.

How much does precise laser cutting cost?

It is difficult to clearly determine the price of the laser cutting process used in the thermal processing of sheet metal. The cost of using the laser sheet metal cutting service is actually closely related to the project – quantity, material, dimensions. Nevertheless, steel laser cutting is a more cost-effective option than traditional machining. This results, among others, from the fact that the automation of the laser sheet metal cutting process allows you to reduce the risk of making costly mistakes and the cutting process itself, lasts incomparably shorter.

Companies interested in laser processing of sheet metal and other materials can obtain more information by contacting Marxam Project – laser cutting company with decades of experience. The guidelines for the project will allow you to estimate the costs of its implementation – we have innovative equipment for laser cutting sheet metal and we guarantee high quality of services provided. We invite you to cooperate with us!

Laser cutting of 3D

Laser cutting of 3D pipes and profiles

Nowadays, the metalworking process is carried out using modern equipment. An example is the precise laser cutting of pipes, profiles sheets using innovative devices equipped with a laser beam.

Marxam Project recommends checking in practice the services of laser tube processing and laser 3D profile cutting, which guarantees a much higher quality of project implementation than traditional methods. Laser cutting in industry of metalworking, is constantly evolving, which is why these technologies offer the most innovative solutions to customer’s needs.

Pipe cutting, profile processing and 3D laser

The dynamic development of technology has meant that the devices used in the metalworking industry offer a completely new quality of services. A perfect example is 3D laser cutting. It is not difficult to guess that the 2D technology allows the processing of materials used in flat elements, e.g. sheet metal. The 3D laser for profiles allows you to process profiles or pipes, which means that it works well in spatial projects. What’s more, laser pipe cutting and profile cutting is much faster and more effective than traditional methods of processing. It is no wonder that more and more companies decide to use this type of service and entrust laser cutting of pipes and profiles in mass production to 3D machines.

Precise laser pipe cutting and sheets cutting with a 3D laser – advantages

The 3D laser works equally well in two- and three-dimensional projects.

- The laser beam can be used in various types of materials, both metallic and non-metallic (structural steel, stainless steel and aluminum).

- Automation of the profile processing and pipe cutting process guarantees fast project implementation.

- High accuracy guarantees minimization of costs, e.g. in the case of preparing sections for further production – it is very helpful when we want to use pipe welding.

- Laser processing of profiles allows you to reduce unnecessary waste of materials and avoid costly mistakes.

- Material processing with the use of a laser beam does not cause too intense heat impact on the material, which in turn reduces its deformations and allows it to maintain its mechanical properties, e.g. cutting closed profiles and pipes ensures the appropriate smoothness of the cut surface.

Laser 3D Profile cutting and welding

3D pipe cutting will work not only as cutting profiles at an angle. Marxam Project offers a service of innovative welding of profiles, pipes and spatial elements using laser radiation. Innovative machines guarantee flexible functionality, which means the ability to easily change the operating mode of the device from precise cutting of pipes and sheets to welding or surfacing. This is an undoubted advantage that allows you to maximize production efficiency. On the other hand, the high level of dynamics of the optical cutting system leads to a significant reduction in time, e.g. during laser processing of pipes and profiles.

Laser tube cutting services - rotational nature of work

Another advantage of laser cutting or welding of profiles is the option of a rotary mode, which can be used in the case of serial production. Automation and repeatability do not only refer to the quality of the final effect. The equipment used by Marxam Project allows for full mechanization of the process of loading and unloading the processed material without any difficulty. This is another proof of shortening the time needed to complete the project. Then the company commissioning the service receives the finished product much faster, which in most cases translates into higher profits, e.g. due to cost optimization and increasing production capacity, making it a perfect solution for industrial laser cutting.

Laser profile cutting and tube cutting – application

The service of laser cutting tubes, pipe welding or profile processing using a 3D laser will work in various industries. Marxam Project constantly cooperates with companies from the automotive, aviation, construction, railway and medical industries – all those who need help in the field of laser processing of flat sheets, pipes or profiles. If you are interested, please contact us.

waterjet

Waterjet cutting

Various technologies are used in the processing of materials. One of them is water treatment, which is one of the basic services of Marxam Project. Customers appreciate water jet cutting, which is due to the fact that this process guarantees a number of benefits when processing the material.

Waterjet cutting - what is it?

Abrasive blasting (so-called waterjet cutting) is one of the modern materials processing technologies. The essence of water treatment is the use of a water stream with extremely high pressure (approx. 4000 bar). The generated jet is passed through a nozzle with a small diameter, which makes it reach three times the speed of sound! It is not without reason that aqua cutting is considered one of the most effective cutting methods. What is worth emphasizing, is that cutting with water guarantees an incredibly high quality of the machined surface for details with large thicknesses and complex geometric shapes.

Waterjet cutting – for which materials should aqua jetting be used?

Aqua jetting will work in virtually most building materials, which determines the universal application of this technology. The waterjet cutting services are recommended in the following cases:

- structural, alloy and tool steels,

- materials sensitive to high processing temperatures,

- glass,

- rubber,

- polycarbonate,

- cast iron and cast steel,

- conglomerates,

- stoneware tiles,

- from synthetic materials,

- titanium and titanium alloys,

- ceramic materials,

- copper, brass and bronzes,

- molybdenum and molybdenum alloys,

- wood and wood-based materials (eg MDF, plywood).

High pressure water jet cutting – advantages

First of all, it should be noted that water jet stainless steel cutting is a cold working method. This means that high pressure water jet cutting steel, does not cause problems in the form of deformation and changes in materials caused by thermal factors. In addition, the water cutting service does not lead to the formation of hot zones and stress on the processed material. What’s more, in the case of extremely delicate materials (e.g. glass) there is no fear of unsightly splinters.

Water cutting service is also an extremely environmentally friendly method. During cutting with water pressure, natural and chemically inert abrasives are used, which means that the machining process itself does not result in the formation of toxic waste. At this point, it is also worth adding that abrasive treatment ensures greater safety for employees – when cutting by water, no fumes or dust are generated that may have an adverse effect on human health.

Abrasive blasting, because this is how the water jetting cutting process is often referred to, is characterized by high quality of cut edges (so-called no burrs on the edges, high class of edge smoothness). Cutting with water jet is not the fastest cutting method (compared to plasma or laser cutting), but it can be used wherever traditional thermal cutters are unable to do their job (based on type of material or its thickness).

Pressurized water cutting – application

The water jet cutting companies provide their services in various industries, e.g. automotive, furniture, electronics, construction, aviation and machinery. Nevertheless, metal water jet cutting works well in less obvious issues, e.g. processing of highly frozen meat or making decorative elements in art. Marxam Project offers water jet cutting of stone, glass, tiles and many more using modern waterjet cutting equipment. If you are interested in business cooperation, please contact us and learn about our offer.