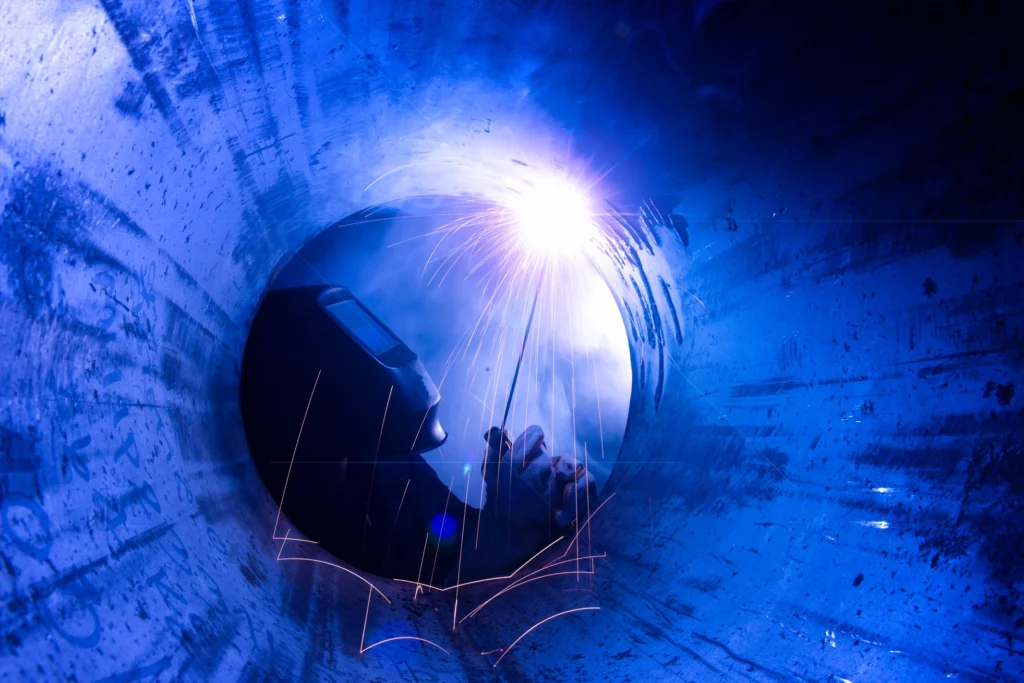

A welder is a person whose task is to join together metal, steel, cast iron and aluminum elements using the permanent connection method. A very important aspect in the welder’s work are manual skills, high patience and self-discipline during the welding process.

This is one of the most difficult and, until recently, the least appreciated professions. Not everyone can become a welder. Very often, and rightly so, welding is compared to artistic work. In addition to high manual skills, you need to have a very broad technical knowledge about the types of materials, the behavior of different types of elements and the behavior of the material in high temperature environments.

marxam project

Permanent connections

Permanent connections

Welding

(structural steel, stainless steel and aluminum)

The steel welding process is a key technology for the production of metal structures.

In our plant, we weld stainless steel structural elements, as well as entire structures made of structural steel, stainless steel, aluminum and aluminum alloys. The main welding types used by our welders are:

- a) arc welding with a consumable electrode in the shield of inert gasses (MIG welding) and active gasses (MAG welding);

- b) arc welding with a non-consumable electrode in protective gasses (TIG welding);

- c) 3D laser welding.

The specificity of the welding services and its belonging to special processes mean that it is carried out in our plant only by qualified employees who undergo regular training to improve their qualifications. The uncompromising approach allowed us to weld in industries with increased requirements: automotive, aviation and railway.

Our personnel is authorized to perform VT1 and VT2 non-destructive tests for the product sector: (c), (f), (t), (wp), in industrial sectors: manufacturing, pre- and operational testing, including manufacturing, which allows for continuous control of the welding process (currently, the training and certification process for PT and MT control is in progress).

For our welding company, the next year will mean the beginning of the implementation process of “Recognition of welding technology according to PN-EN ISO 15614:2008.”

In the metal welding process, we can also use a welding robot, which allows us to achieve high repeatability and welding quality for small and large production series.

The key technology for the production of metal structures.

do you need this service?

Alternative methods of joining metal elements.

Permanent connections

Spot, capacitor

and induction welding

Our spot welders allow the use of alternative methods of joining metal elements. Resistance spot welding is one of the most popular techniques for joining thin-walled metals.

The use of condenser welding machines allows for quick and easy mounting of fasteners (pins, screws, pins) on the surface of metals.

Induction welding allows you to significantly reduce energy consumption, and thus reduces the cost of manufacturing details. This process significantly reduces the area of thermal action, which contributes to easier cleaning of the joined areas. Induction welding technology allows for its automation, which makes the process repeatable and simpler (and therefore cheaper).

Thanks to the use of alternative methods of joining materials, we are able to offer our services in the construction industry; transport of liquids and gasses; automotive industry and machine manufacturing.

do you need this service?

welding

Welding (structural steels, stainless steels and aluminum)

Aluminum welding, welding stainless steel, structural metal welding – yes, we can do it all and even more.

The welding process, i.e. the joining of fusible materials, is no mystery to us. And even if we come across one, we will gladly get to know it and introduce it to our plant.

The welding process is our passion and therefore we strongly encourage you to take advantage of the experience and skills of our team of welders. As a welding company, we are ready to take on any challenge.

What is MIG welding and when is it worth using?

MIG welding is an extremely popular method of joining sheets, pipe welding, welding profiles and a number of other elements that are made of low-carbon steel, stainless steel, acid-resistant steel or alloy steel. The MIG welding technique consists in the use of an electric arc, which is formed between the welded surface and the wire (consumable electrode). A characteristic feature of structural steel work with this method of sheet metal welding is the use of a shield of chemically inert gas, which does not participate in the process of joining materials. The most commonly used gasses are argon or helium, which make the welded structure’s design be as close to original as possible.

MIG welding is often the favorite way to weld stainless steel of thin thickness, but which method is ultimately used depends only on the customer’s requirements.

What is MAG welding and where is it used?

MAG welding is similar to the previously mentioned MIG welding technique. An electric arc also forms between the consumable electrode and the workpiece. The difference, however, is that chemically active gasses, such as oxygen or carbon dioxide, are used in MAG welding. This property allows you to use this technique for joining sheets or welding of pipes and profiles that are made of non-alloy, low-alloy or high-alloy structural steel.

MIG/MAG structural steel welding - advantages

- High process efficiency.

- Good quality of the obtained weld.

- Universal use – MIG welding and MAG welding can be used in a variety of metals and their alloys and in a variety of positions.

- The processes of welding rods, profiles, sheets or welding angles and other structural elements can be automated, which guarantees a low risk of errors, reducing the chances of material losses, reducing costs and high repeatability of work – an ideal solution for serial production where metal processing is the heart of the production plant for any steel fabricator.

What is TIG welding and what is it used for?

Sheet metal joining looks a bit different when TIG welding is involved. Although this also uses an electric arc, the difference is that it is formed between the component and the non-consumable tungsten electrode. The entire process of structural steel fabrication, e.g. sheet metal welding or steel welding takes place in a shield of chemically inert gas, e.g. argon or helium. A characteristic feature is obtaining a weld that is characterized by the absence of impurities and high quality. TIG welding is mainly used to join sheet metal or other structural elements made of metal of small thickness. The TIG method is mainly used for stainless steel and metal materials, for which it is necessary to use a chemically inert protective gas, e.g. aluminum, copper, nickel or titanium. Currently, this method is often associated with pulse TIG welding and TIG aluminum welding.

Welding services using the TIG method - advantages

- No liquid metal splash.

- Possibility of automation and mechanization of the welding service.

- Possibility of welding sheets with an extremely small cross-section (from approx. 0.5 mm).

- Versatile use – TIG welding will work in a variety of metals and their alloys, as well as in different positions.

- Extremely high quality of the weld (high strength) and unique purity, aesthetics and correct shape of the joint obtained. It can be said that with this method welding goes to a higher level.

Welding structural steel, of profiles and sheets at Marxam Project

Marxam Project employees, who are responsible for the implementation of sheet metal joining projects, welding structural steel, sheet metal and profile welding, regularly improve their qualifications. This is possible through participation in cyclical training. All welders and employees of the technical department are authorized to inspect VT1 and VT2 – while in the near future the process of training and certification for PT and MT inspection will begin. What’s more, Marxam Project has a welding robot. Thanks to this, we can ensure that many different welding types in industries with high requirements (e.g. automotive or aviation) will be characterized by a high level of repeatability and the necessary quality. Therefore, metalworking becomes fully complete. We offer welding services for small and large serial productions. Welding and metal fabrication is supported by a new company and welded structures receive help even in emergency cases, we also offer spot welding of stainless steel, aluminum and other material, do not hesitate to contact us.

capacitor welding

Spot welding, capacitor welding and induction welding

Welding is a process that consists in making a permanent connection of structural elements or parts of devices that are made of metal or plastic materials. Sheet metal welding in the metallurgical industry takes various forms of joining (e.g. spot welding or induction welding), which are characterized by different procedures for execution or application in practice.

Marxam Project offers professional spot, capacitor and induction welding services, which are performed using high-end equipment. If you are looking for a spot welder for aluminum, then look no further, we offer a wide variety of high quality services.

What is spot welding?

Spot welding is one of the most popular forms of joining metallic and non-metallic materials. Welding steel in this way is a spot welding process, which consists of pressing together structural elements or parts of devices using welding electrodes. The heating electrodes cause heating of the elements at the joint – then the surfaces transform from a solid state to a plastic state (resembling dough) and a weld nucleus is formed. When the core cools down, a uniform and permanent connection between the elements is created. It is worth emphasizing that the plasticization of the material occurs only at the contact edge. Welded connections made by our company use welders that enable the use of various methods of joining metal structures. Resistance spot welding is one of the most commonly used methods of joining thin-walled metals and materials, up to 3 mm thick. In this way, aluminum spot welding, steel welding and spot welding of stainless steel can be performed.

What is inductive welding?

One of the forms of spot joining of metal elements is induction welding. Electric welding of this type is a process where electromagnetic induction is used. Marxam Project offers metal welding by induction joining, which guarantees a lot of benefits for the project:

- Inductive welding allows for a real reduction in energy consumption, which translates into lower costs when creating details and minimizes the size of the area subjected to thermal action.

- Thanks to inductive joining, the time needed to heat the connected elements is reduced, and this is an additional way to reduce the final price of the production process.

- Spot welding using electromagnetic induction guarantees much easier cleaning of places subjected to the welding process (which is very important when we have to perform, for example, welding nuts or welding pipes).

- Inductive welding creates the possibility of automating activities – production is characterized by a high degree of repeatability and simplicity, which means a significant reduction in final costs.

Induction welding is often used in the pipe industry. Usually this type of welding is used to join elements made of aluminum, low carbon and low alloy steel as well as non-magnetic and magnetic stainless steel.

What is capacitor welding

The use of condenser welding machines is another method of spot joining metallic materials. This method ensures quick and uncomplicated assembly on the surface of elements used to fasten other components, e.g. screws, pins, pins. We differentiate capacitive discharge welding, which is a special type of joining, in which the energy in capacitor discharge welding is provided by a large capacitor bank.

Spot welding – application

Marxam Project uses a wide variety of spot welding methods for metallic materials. Our services have been used e.g. in the automotive industry, in machinery production plants, companies responsible for the transport of liquids and gasses or in the construction industry. We provide spot welding of batteries (welding battery tabs), tig spot welding, spot welding with mig and many others. Spot weld in our company is of high quality, made by experienced professionals with decades of experience in the field. We carry out individual orders and serial orders – in both cases, we focus on high quality workmanship and minimization of costs for the customer.